The Ins And Outs Of Automated Conveyors

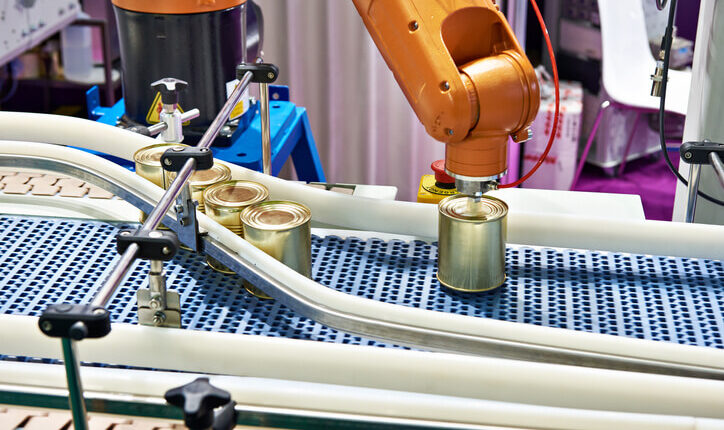

In businesses that rely on repetitive processes to manufacture, move or assemble items into products, owners and managers will want to take advantage of automated systems to reduce errors, improve efficiency and boost safety and security.

For this reason, manufacturers, technology companies and a whole range of businesses both large and small will find it essential to work with automated conveyors. Automation not only allows you to accomplish more with fewer employees, but also it can help you more effectively reach the goals you’ve set for key performance indicators.

Whether you work in B2B, retail or wholesale, automation is an instrumental way to deal with worker shortages as you strive to meet strict standards for safety, quality and efficiency on your production line.

If your organization is just getting started investigating the idea of installing and using automated conveyors, here’s a review of the ins and outs of this technology.

Tracking the Details

An automated conveyor system equipped with sensors will make it easy for your organization to read bar codes as products move through the line.

You can also keep track of the weight of objects, which helps verify the system is working with the right item (100 grams versus 1 kilogram, for example) as part of your error-correction checks.

With the conveyor noting the weight of objects, you’ll also be able to determine shipping costs on the fly, which is a process that’s excellent for your efficiency statistics.

Better Safety

Taking humans out of the equation so automated equipment handles the movement, sorting and packing helps improve your company’s safety record, which is instrumental in recruiting new workers.

The automated equipment boosts safety further by letting you scan for dangerous items, such as metal fragments detected by sensors automatically triggering the system to pull contaminated food products off the line.

Ease of Packing

You can set up your automated conveyor system to bring items to the end of the line for packing, where they will go into envelopes, bags, cartons or boxes. The system is reconfigurable, too, so you can switch between poly bags or handling trays, for example, as you handle different types of items or work on product runs for customers with widely varying packing requirements.

With the machinery programmed to handle picking and processing processes, you can easily set up the most efficient bundling of products as they move out the door for distribution.

Connecting Multiple Lines and Processes

In many cases, companies will need to coordinate the action of multiple production lines to deliver their finished items. With junction conveyors installed at your facility, you can connect one line to another. This works in vertical formats and horizontal layouts, so you can be more flexible in your industrial design.

A Place for Automated Conveyor Equipment in Your Facility

Relying on humans alone to move items through your company is old fashioned and results in a process that’s prone to error and safety issues. To boost quality control efforts and speed up production, you’ll want to deploy an automated conveyor system. Its sensors will help you keep track of the weight of each item and the name of each product thanks to barcode scanning capability.

The flexibility you can achieve with automated conveyors means you can divert products to wind up in cartons, bags, totes, trays or boxes. Automated picking and packing and the ability to program the most efficient approach to kitting items will let your organization work more nimbly, to quickly reconfigure how the line processes products.

And since automated conveyor systems do not need to take sick days or leave for vacations, you can count on a more stable workflow in your facility than if you only relied on people to do sorting and conveying.

Author bio:- Chris Thompson is Senior Marketing Communications Manager for QC Conveyors. He joined the team in 2005 and currently leads marketing efforts for QC Conveyors and FMH Conveyors, working at the intersection of material handling and industrial automation.

Comments are closed.